O Ring Durometer Pressure Rating

Generally most rubber materials fall under the rubber durometer scale of shore a.

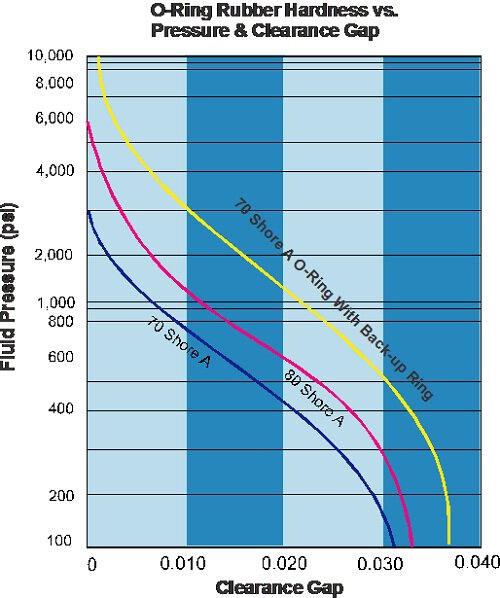

O ring durometer pressure rating. Techniques to avoid extrusion in high pressure applications include decreasing the clearance gap increasing the elastomer modulus mod 100 and the use. For most applications compounds having a durometer hardness of 70 to 90 is the most suitable compromise. Duro 40a pencil eraser. Shore 20a rubber band.

A rubber durometer of shore 70a is the most commonly chosen material hardness for all applications. Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a. Duro 20a rubber band. Generally most rubber materials fall under the rubber durometer scale of shore a.

Harder materials like 70 75 or 90 durometer compounds offer greater resistance to extrusion. The indicating scale reads the hardness of the rubber. Parker recommends using 6 times the cross section of the seal for example 1 260 for an o ring with 0 210. The durometer has a calibrated spring which forces an indent or point into the test specimen against the resistance of the rubber.

A rubber durometer of shore 70a is the most commonly chosen material hardness for all applications. Duro 60a car tire tread. At very high pressures the seal must have sufficient strength to resist extrusion into the clearance gap. A rubber durometer of shore 70a is the most commonly chosen material hardness for all applications.

The chart at right illustrates the recommended limits of the combination of clearance gap diametral seal hardness and pressure differential. When using a regular round o ring in a rectangular groove path what minimum radius should i use at the corners. In dynamic applications the hardness of the o ring is doubly important because it also affects both breakout and running friction. Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a.

If there is no penetration the scale will read 100 as on a flat glass or steel surface. Most elastomeric seals are designed to operate within ambient pressure to about 1 500 psi.