O Ring Durometer Tolerance

The higher the durometer the harder the compound.

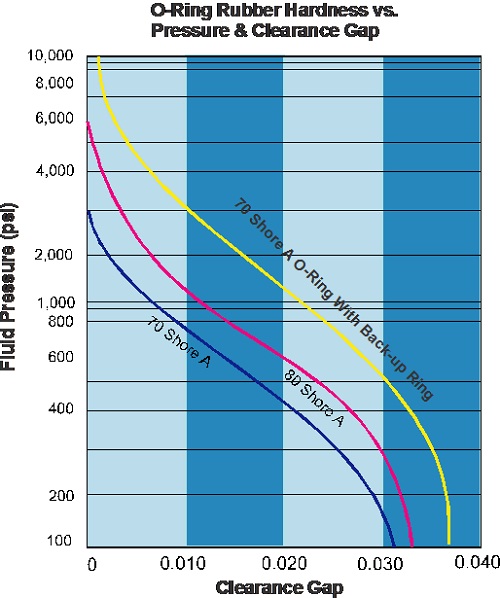

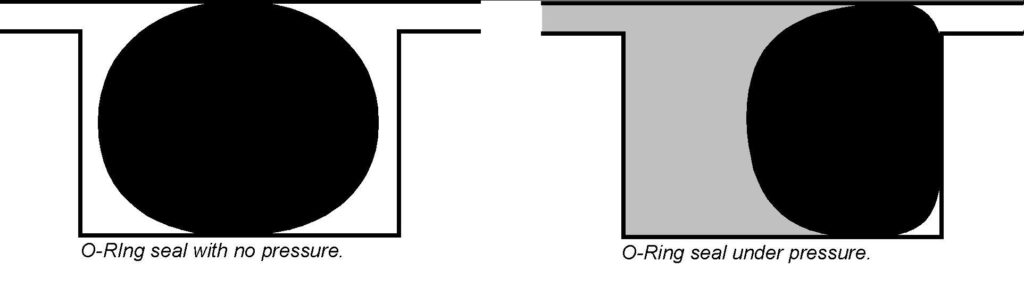

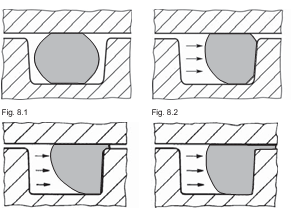

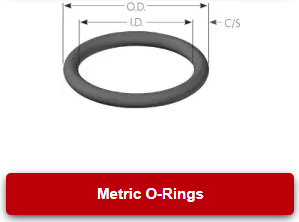

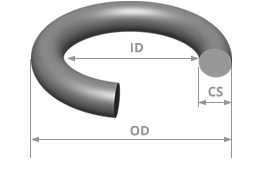

O ring durometer tolerance. 3 classes of o ring cord tolerances. Low durometer o ring low durometer o rings have less tolerance for high pressure and the subsequent risk of extrusion but if the hardware maintains a zero clearance gap the softer o ring material should perform as well as the higher durometer seal material do this of course assumes the plates are flat and are not causing extrusion. Low durometer o rings have less tolerance for high pressure and the subsequent risk of extrusion. Should not exceed 3 of the rod gland diameter for o rings with an i d.

Smaller than 250 mm. The hardness of rubber compounds is measured by the shore a durometer. Durometer shore a scale is a type of measurement for rubber material hardness. Generally most rubber materials fall under the rubber durometer scale of shore a.

O ring cord is extruded through a die in a variety of thicknesses or cross sections. But if the hardware maintains a zero clearance gap the softer o ring material should perform as well as the higher durometer seal material does. It is an industry standard test for rubber and it is an acceptance criterion for every batch of o ring material mixed by parker. Low durometer o ring promoparker.

For o rings with an i d. The hardness of rubber compounds is measured by the shore a durometer. 2 the inherent minor variance from batch to batch of a given rubber compound due to slight differences in raw materials and processing techniques. A durometer scale is a type of measurement for rubber material hardness.

Softer compounds stretch easier and seal better on rough surfaces. The higher the durometer the harder the compound. The higher the durometer the harder the compound. 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.

Greater than 250 mm or 5 for o rings with an i d. What is durometer shore durometer. 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications. What is shore a hardness and how is it tested.

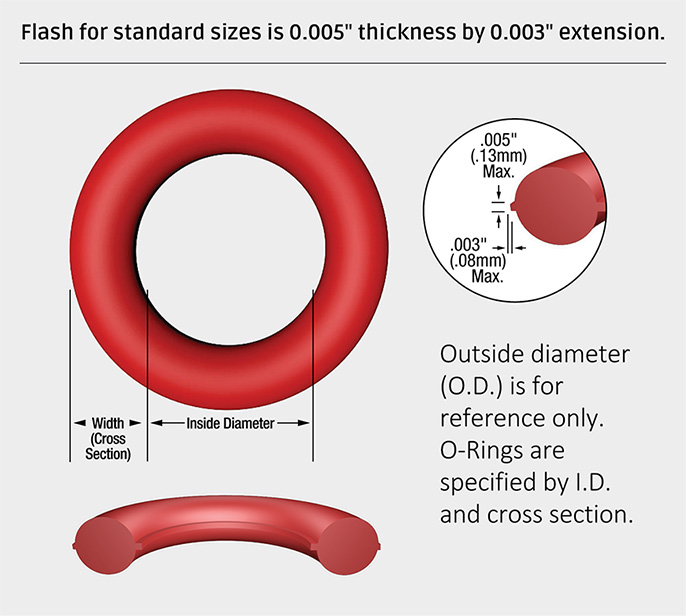

Shore a hardness testing is performed using a durometer which was developed by albert ferdinand shore in the 1920s. 1 the fact that durometer is generally called out in specifications with a tolerance of 5 i e 65 5 70 5 90 5. The hardness of rubber o ring compounds are measured by the shore a durometer. Extruded o ring cord stock is used for a variety of applications whenever a molded o ring is impractical for one reason or another.

This extrusion process used to make o ring cord has many advantages however it can be difficult to achieve a consistent precise thickness throughout the length of the cord. Smaller than 20 mm this is not always possible due to tolerance issues which can result in a greater o ring o d. This of course assumes the plates are flat and are not causing extrusion gaps.