O Ring Durometer Vs Pressure

The only time you will design for a back up ring on one side is when there is not enough space for two rings.

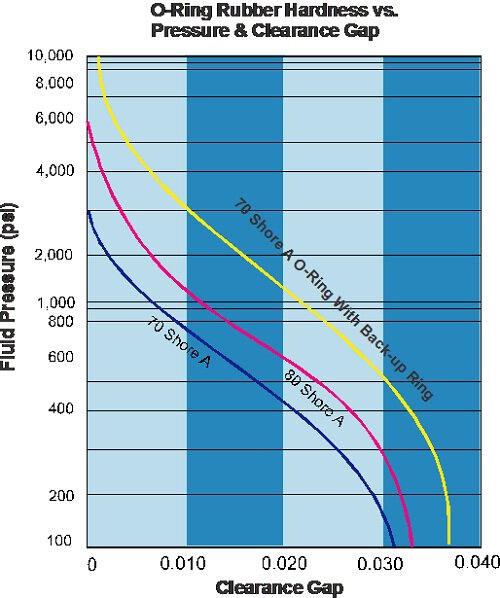

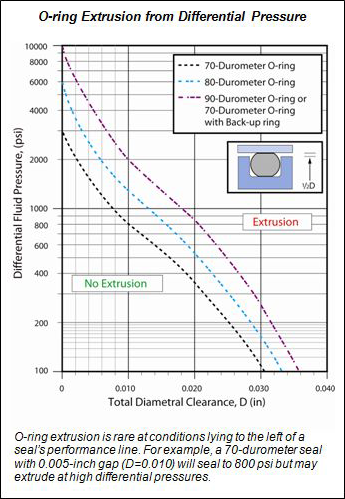

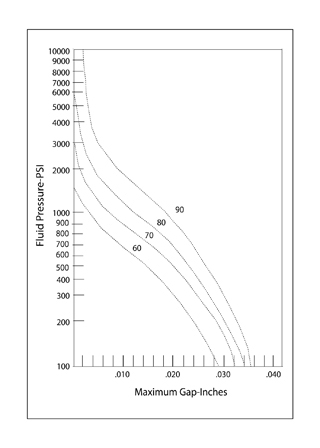

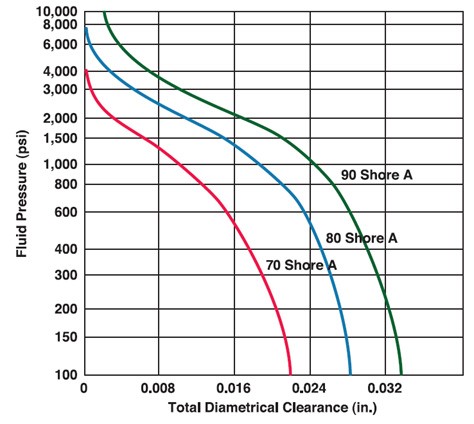

O ring durometer vs pressure. O ring gland clearance gap size. The durometer has a calibrated spring which forces an indent or point into the test specimen against the resistance of the rubber. O ring application pressure vs. Excessive clearance and or pressure can result in sealextrusion and failure.

O ring durometer vs pressure and clearance gap groove design reference. Rt dygert often fields technical questions about how much pressure an o ring can withstand before it fails. A buna n 101 o ring in a static face seal might have a different maximum pressure rating than a silicone one used on the od of a reciprocating piston. 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.

Consider use of back ups or product selection with large gaps or pressure. Unfortunately there is no easy answer for the maximum operating pressure because this pressure is highly dependent upon the design parameters of the application. When using a regular round o ring in a rectangular groove path what minimum radius should i use at the corners. Parker recommends using 6 times the cross section of the seal for example 1 260 for an o.

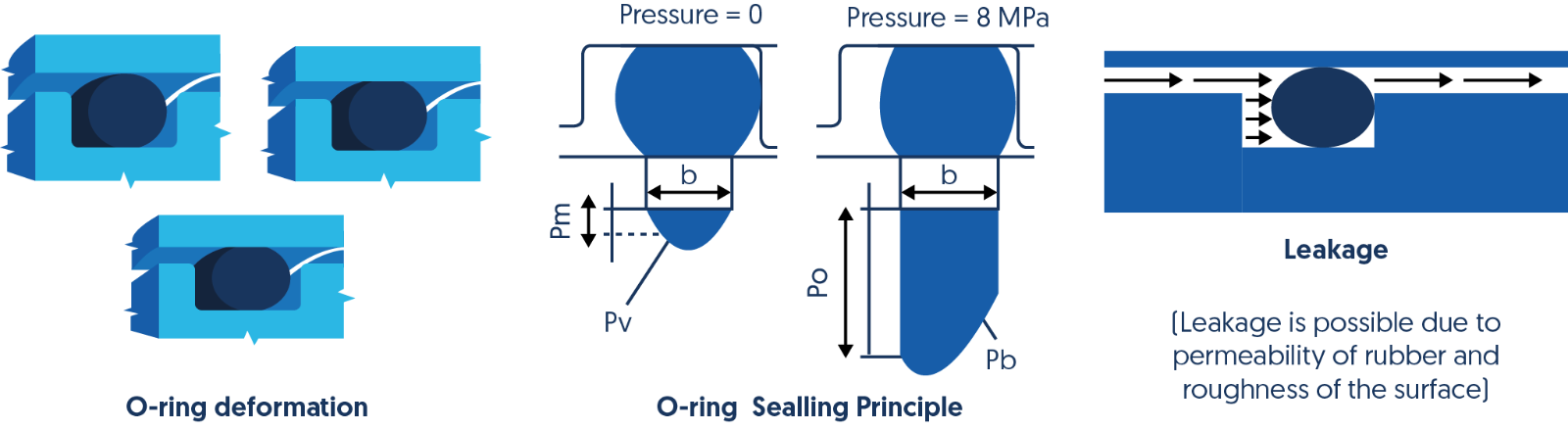

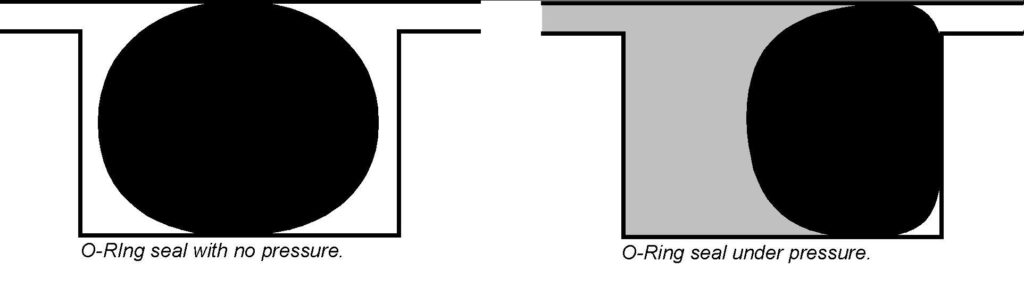

The hardness of rubber o ring compounds are measured by the shore a durometer. Ms 28783 back up rings match the dash numbers an an 6230 o rings. At very high pressures the seal must have sufficient strength to resist extrusion into the clearance gap. If there is no penetration the scale will read 100 as on a flat glass or steel surface.

Durometer shore a scale is a type of measurement for rubber material hardness. Pressure and clearance gap chart. The higher the durometer the harder the compound. A specially designed o ring system could withstand pressures of 5000 psi or greater however.

Tolerances should be considered for the o ring and the gland. 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications. Good practice is to use a back up ring on either side of the o ring even though the pressure on the ring may be from one side only. Use our extrusion chart to determine if the maximum recommended pressure of an o ring seal based on your seal hardness and gland clearance.

The indicating scale reads the hardness of the rubber. 25 durometer rubber band 55 durometer inner tube 70 durometer most common rubber tire rubber shoe heel 95 durometer shopping cart wheel. As hydtools points out you should take a good look at the parker o ring handbook. The higher the durometer the harder the compound.

The hardness of rubber compounds is measured by the shore a durometer.