Oil Diffusion Pump Pdf

222 40 part no.

Oil diffusion pump pdf. 227 50 t no. Glass oil diffusion pumps 924770 924780 924785 924795 instruction sheet number 9247895. In all diffusion pumps a small amount of. High throughput gives high pumping speeds at.

Gases on the high vacuum inlet side of the pump are captured in the jet vapor by diffusion and are carried from upper to the lower jet stages which compresses them. 227 70 t no. Oil vapor diffusion pumps it wasn t that long ago when you could walk into any vacuum laboratory and find a vapor diffusion pump on every system. 227 65 t no.

The downward shooting vapor travels at an incredible 750 miles per hour sometimes breaking the sound barrier one mach. This application note will explain practical steps that can be taken to ensure optimal. Yet oil diffusion pumps require careful maintenance in order to maintain a high level of performance and maintain the integrity of the vacuum chamber. 222 20 part no.

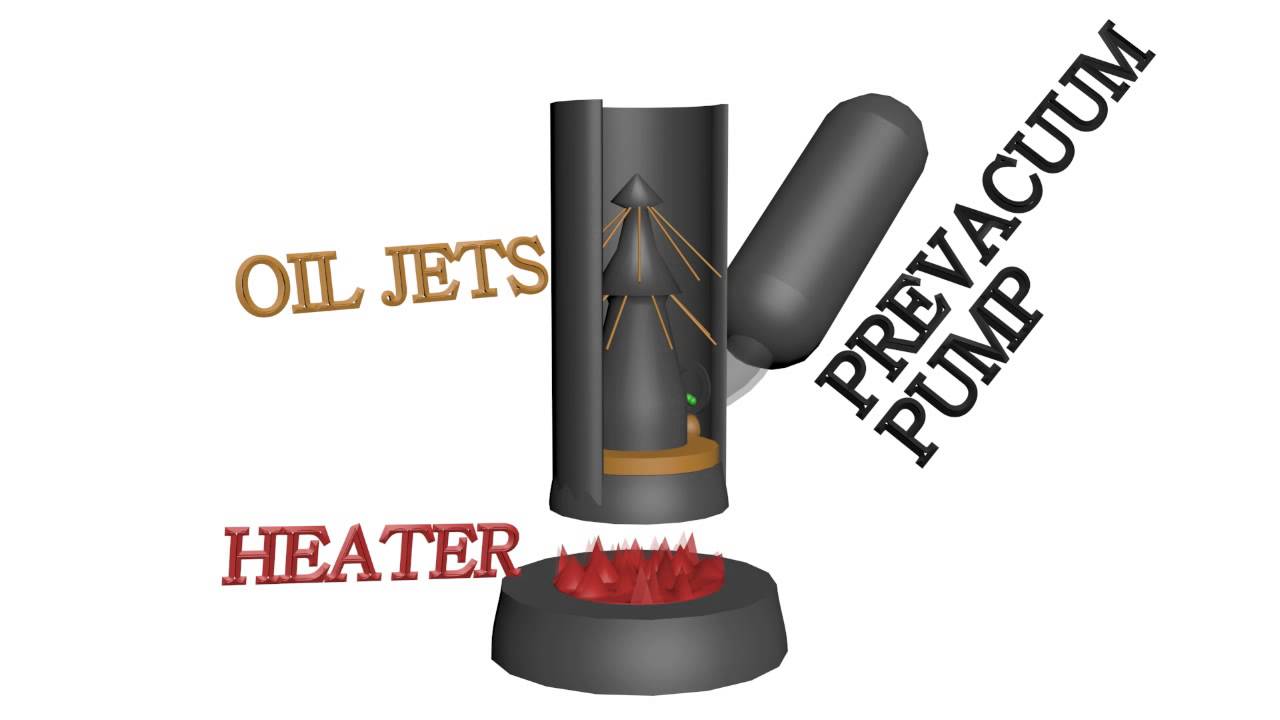

222 10 part no. Oil vapour diffusion pumps vapour pumps for industrial applications edwards has long been a pioneer of vapour pumps and diffusion pump technology with innovations such as the diffusion pump cold cap and the combined diffusion pump the diffstak. Vapor diffusion pumps were first conceived about 1915 16 and used mercury as the pumping fluid. The oil diffusion pump consists of a pump body boiler heater and 3 stage fractionating jet stack assembly.

227 60 t no. Fluid flows through the boilers in series starting nearest the pump outlet. Edwards s range of high throughput diffusion pumps have many advantages in industrial applications. The excited gas travels upward and exits through the pressure jets that are pointed at an downward angle.

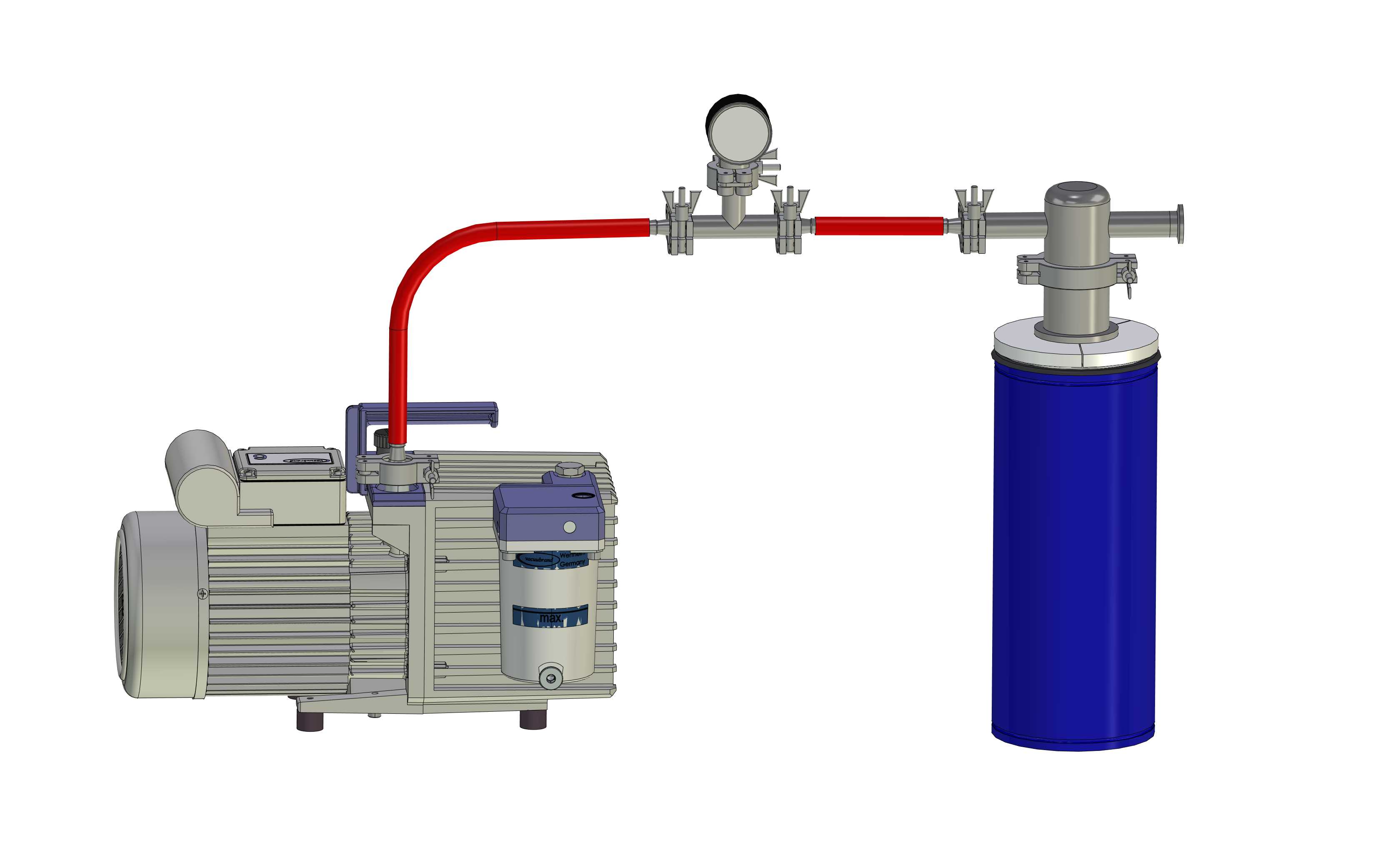

This is because they are relatively inexpensive highly reliable and very durable. Oil diffusion pump astrotorus vapor baffle water flow monitor lr 10 lr 20 never seez thermostatic safety switch contact thermometer thermoelement pt 100 sensor pump fluid see below part no. As the gas. Oil diffusion pumps are still a widely used type of high vacuum pump.

Operating characteristics multi stage fractionation type pumps provide low ultimate pressure through the use of alembics in the outlet tube just above the condensing zone for the vapor jet and individual boilers for each stage. 227 80 part no. 227 75 t no. For pump operation the boiling point of the oil is not particularly important but the thermal breakdown temperature may be.

122 82 part. Oils with low boiling points also tend to have lower thermal breakdown temperatures. A decade later experimenters found that some oils had high boiling points and low vapor pressures and were good pumping fluids. Mercury or oil of high molecular weight are boiled in the boiler a and the vapour streams at high speed across the nozzle c into the pump chamber.

The working fluid oil is heated in the boiler vaporized and streams out of each stage of the jet stack at high speed. 222 25 part no. The sketch of a diffusion pump is shown in fig. Since the chamber itself has no moving parts aside from the oil droplets a vacuum diffusion pump can operate with stability over long periods.