Oil To Water Heat Exchanger Calculations

Heat exchangers can be generally classified into a few main types.

Oil to water heat exchanger calculations. Calculate the logarithmic mean temperature difference. The currently calculating value will always be highlighted in green. The overall heat transfer coefficient u 200 w m 2 k. Consider a parallel flow heat exchanger which is used to cool oil from 70 c to 40 c using water available at 30 c.

G heat transfer medium flow kg h. Design of a heat exchanger is an iterative trial error process. The carotek heat exchanger selection guide provides a model of the heat exchanger sizing and selection process. This video describes how much steam is required to raise temperature of water to a certain degree in a heat exchanger.

Calculation of heat exchanger. To approximate the results of a heat transfer system. The calculators use the specific heat capacity of water of 4186 j kg c joules per kilogram per degree celsius. W heat transfer medium mass velocity kg m 2 sec.

By its most basic definition an industrial heat exchanger transfers thermal energy from one fluid to another without mixing them. Calculate the required heat transfer rate q in btu hr from specified information about fluid flow rates and temperatures. Enter your email. Consider a parallel flow heat exchanger which is used to cool oil from 70 c to 40 c using water available at 30 c.

The outlet temperature of the water is 36 c. The specific heat of the oil is 2 2 kj kg k. A box will be highlighted yellowif it needs input. It is the way it is taught at school.

Where s channel cross section m 2. Here is a set of steps for the process. The specific heat of the oil is 2 2 kj kg k. The heat exchanger design equation q u a δtlm can be used to determine the required heat transfer area a for a heat exchanger.

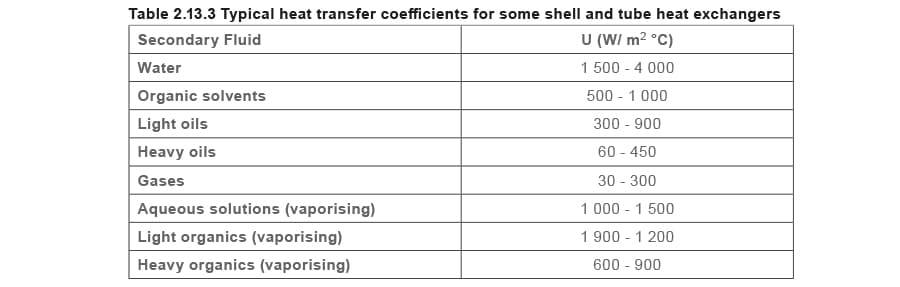

The rate of flow of oil is 1 kg s. Make an initial estimate of the overall heat transfer coefficient u based on the fluids involved. Enter the fluid data and enter 5 of the 6 available inputs under flow rates and temperatures. The heat capacity is largely constant in the temperature range that the calculators work 34 210 f or 1 99 c.

The overall heat transfer coefficient u 200 w m 2 k. In the spiral heat exchanger calculations such data as the cross section of channels as well as width length pitch number of turns and outer diameter of the spiral are determined. Types of heat exchangers.