Oil Water Separator Design Calculation

Api separator calculations.

Oil water separator design calculation. Design flow rate in gpm 250. Specific gravity of the oil in g cm3 0 850. Upgrading 3 phase separators and decanters removing haze from finished products such as diesel and jet fuel oil water separators solvent recovery from liquid liquid extraction towers basic design concepts the emulsion in selecting and designing a coalescer it is important to understand and characterize the emulsion that has to. Chapter 5 oil water separators 5 1 introduction the intended use of an oil water separator s ows determines whether the separator is subject to the spcc regulations and if so what provisions are applicable.

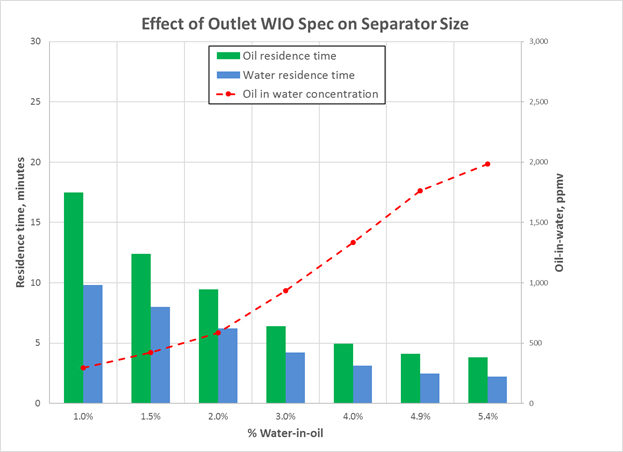

This method which rightfully erred on the side of caution often tended to require facility owners to purchase extremely large separators. Api calculations company location api separator calculations density of the water in g cm3 temp f absolute viscosity kinematic viscosity centipoises centistokes ssu ft sec poise density g cm3 viscosity in poise temperature in deg f design oil droplet in cm terminal velocity in cm s oil droplet size in microns specific gravity of the oil in g cm3. Oil droplet size in microns 150. One of the design parameters for an oil water separator is the minimum size of oil droplet removed from the waste water stream.

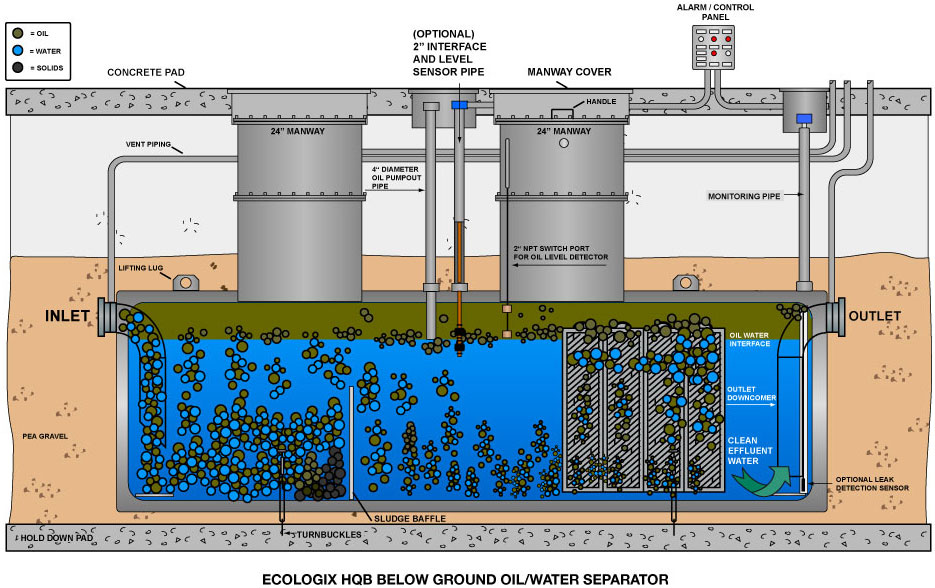

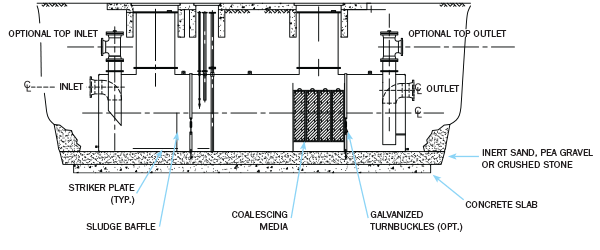

Density of the water in g cm3 0 99890. The most common oil water separator design uses parallel corrugated plates that cause the oil droplets to increase in size and rise to the surface of the water. Removing all oil droplets larger than 150 microns will yield an oil content of about 1 000 parts per million ppm which should be compared with permit conditions. Most cities and counties would size the oil water separators based solely on the square footage of area draining into the separator.

Temperature in deg f 60. Therefore the effectiveness of any oil water separator is affected by the flow rate. This chapter explains the applicability of the spcc. User input in yellow.

The slower the flow the better the results. Design capacity an oil water separator has upper limits to the amounts of oil and sludge that can effectively accumulate while it is in operation. The treatment area should include any areas where contamination by accidental spills of oils greases. Viscosity in poise 0 01129.

The initial step for computing a design flow is to define the areas where contaminated flow will originate. Inputs water wastewater division 100 flow rate gpm formula.

-2_copy-resized-600.jpg)