Oil Water Separator Design Guidelines

Why be concerned about oil water separators.

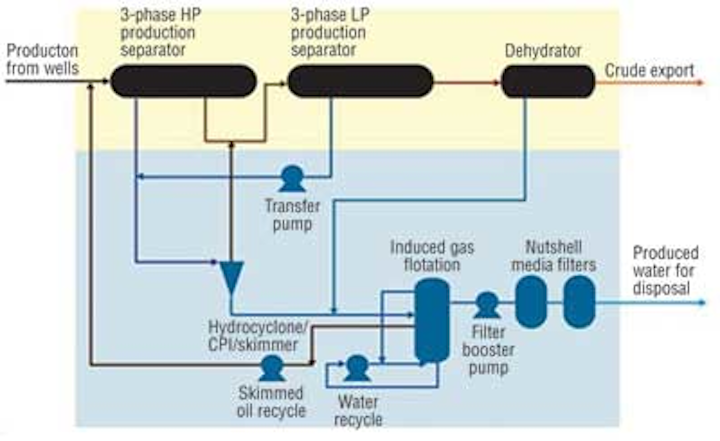

Oil water separator design guidelines. Pollution prevention guidelines use and design of oil separators in surface water drainage systems. The initial step for computing a design flow is to define the areas where contaminated flow will originate. The oil forms a separate layer that can then be removed by skimmers pumps or other methods. Flow rate in general separators are sized by the flow rate verses the separation chamber s effective surface area or.

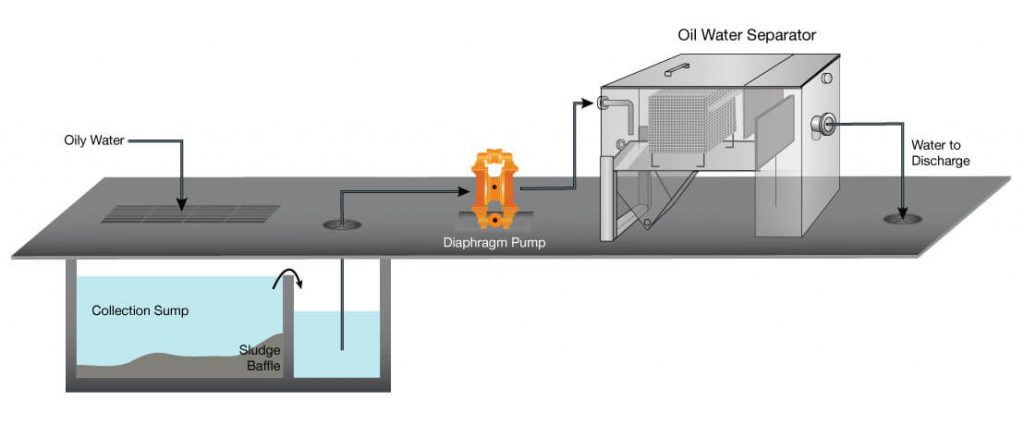

Owss treat vehicle and floor wash water by allowing substances lighter than water to float and substances heavier than water to sink. Following the good practice described does not remove your obligation to comply with relevant legislation. Many owss also have baffles coalescers and oil skimmers to speed up or enhance separation of these substances. The treatment area should include any areas where contamination by accidental spills of oils greases.

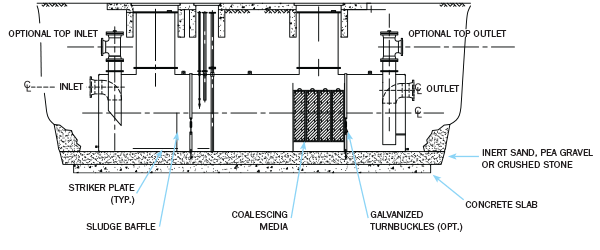

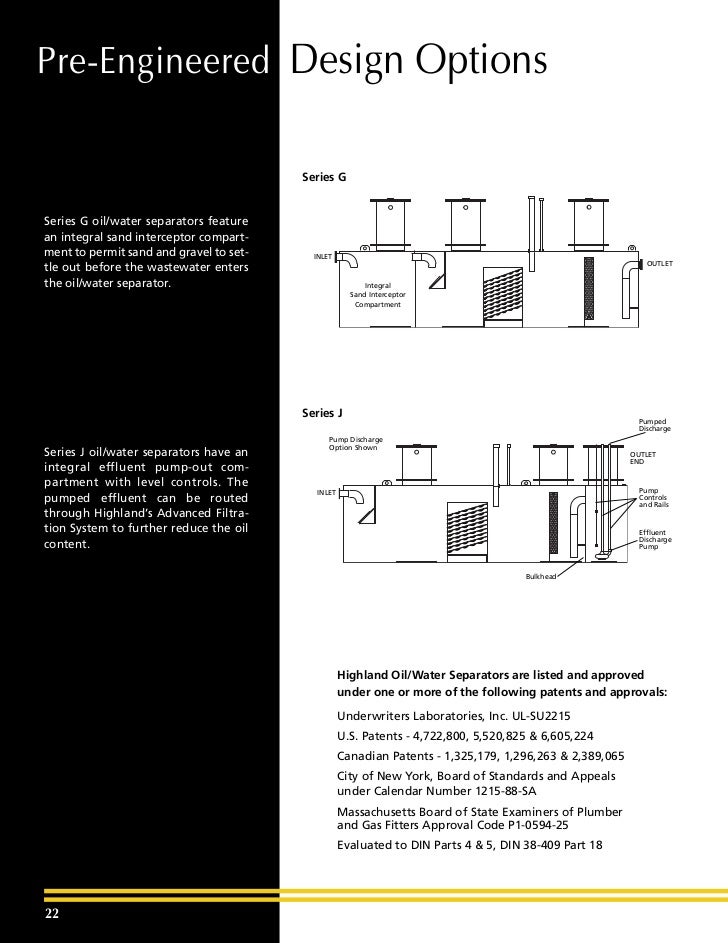

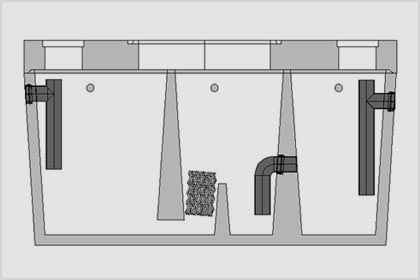

Many technical papers have been written on the hydrocarbon and heavy oil water separator design and vast amounts of information are also available in corporate process engineering design. The forebay is primarily to trap and collect sediments encourage plug flow and reduce turbulence. Based on that design criterion most of the suspended solids will settle to the bottom of the separator as a sediment layer the oil will rise to top of the separator and the wastewater will be the middle layer between the oil on top and the solids on the bottom. Emulsifying agents detergents and soaps designed to.

Design capacity an oil water separator has upper limits to the amounts of oil and sludge that can effectively accumulate. Ppg 3 these guidelines will help you decide if you need an oil separator at your site and if so what size and type of separator is appropriate. A map and description of the facility will help identify the areas where oily water is being generated. The design of the separator is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water.

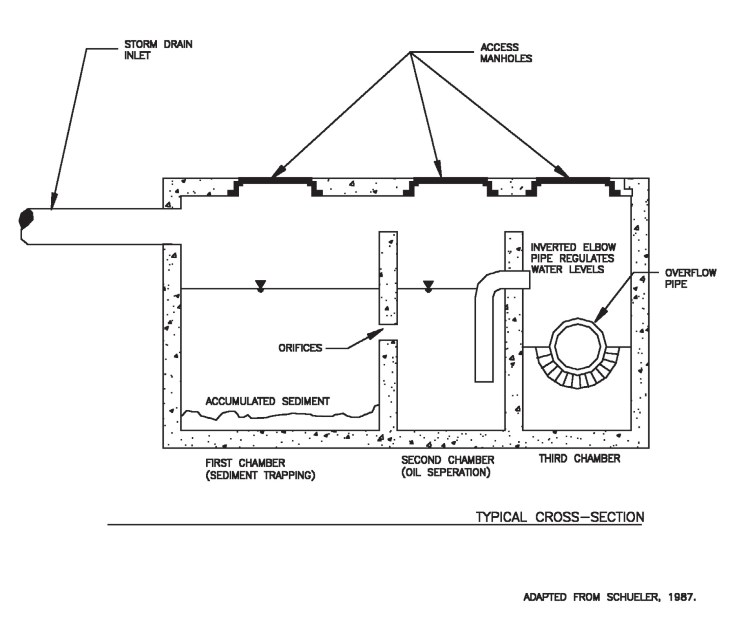

33 2 1 design oil separators shall be divided into three compartments by baffles or berms. Produced well fluid consist s of different ratios of oil water natural gas and sediment. Design of conventional and parallel plate oil water separator systems requires proper characterization of the wastewater establishment of the design flow and required effluent quality sizing of. Separators separator vessel design is a crucial consideration for oil and gas producers trying to separate valuable resources from disposable ones.