Oil Water Separator Design Manual

Separator designs may vary are liquid containment structures that provide sufficient hydraulic retention time to allow oil droplets to rise to the surface.

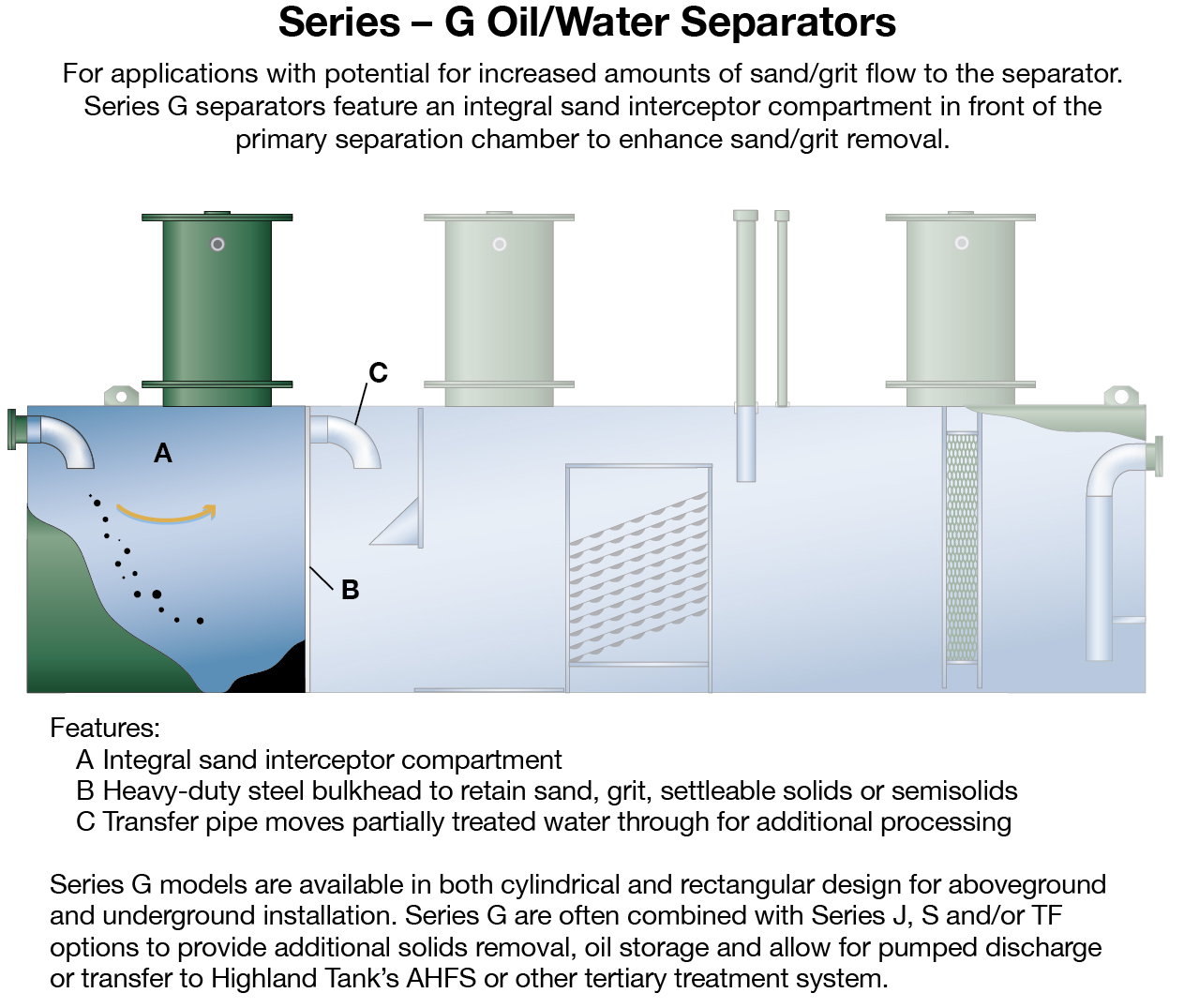

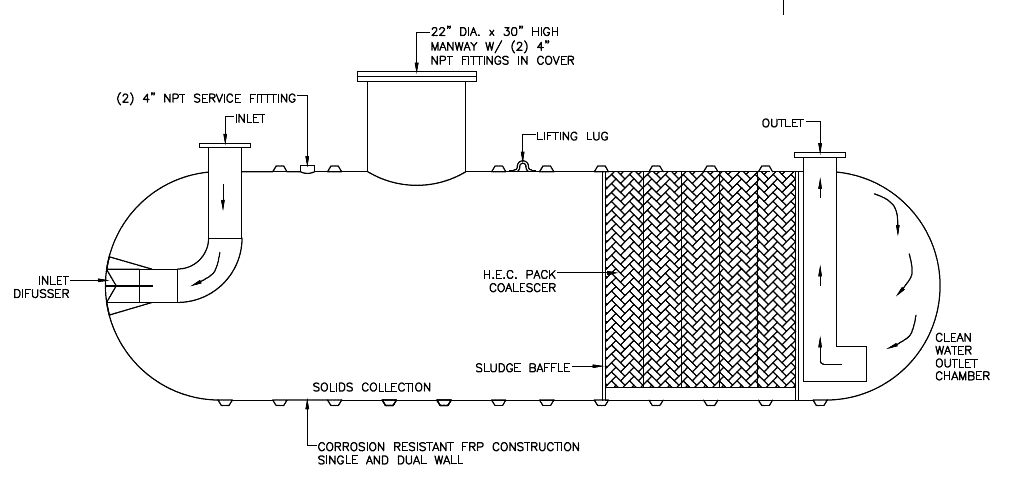

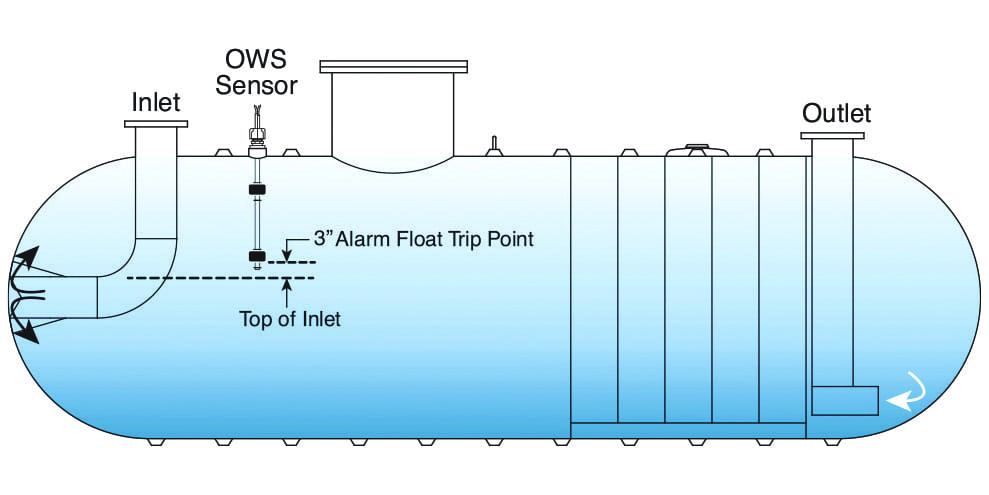

Oil water separator design manual. Three variations are presented in this manual. Design of conventional and parallel plate oil water separator systems requires proper characterization of the wastewater establishment of the design flow and required effluent quality sizing of. The separated water is purified for direct sewer or ocean discharge. A forebay inlet chamber an oil separator cell and an afterbay outlet chamber.

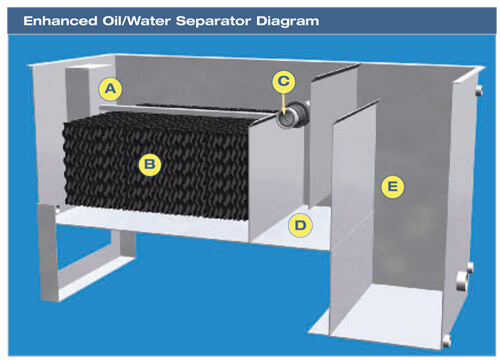

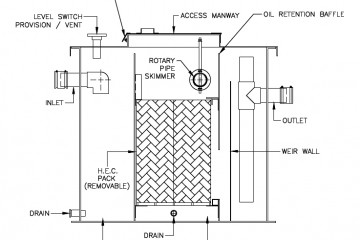

The forebay is primarily to trap and collect sediments encourage plug flow and reduce turbulence. It consists of three major parts the oil separator unit filter unit and the oil content monitor and control unit. This separation of the liquids from the gas phase is accomplished by passing the well stream through an oil gas or oil gas water separator. Liquid liquid coalescer design manual acs oil water separatorsutilize patented technology to separate oily waste water.

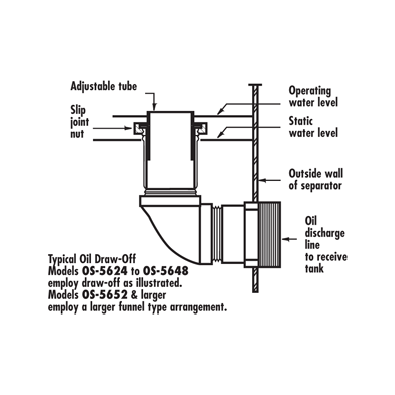

Applications include oil spill clean up for marine power plants refineries vehicle terminals and countless others. The petroleum and water treatment industries as well as the hvac systems employ the various separators in their daily operations. The design utilizes the difference in specific gravity between oil and water buoyancy force. The oil forms a separate layer that can then be removed by skimmers pumps or other methods.

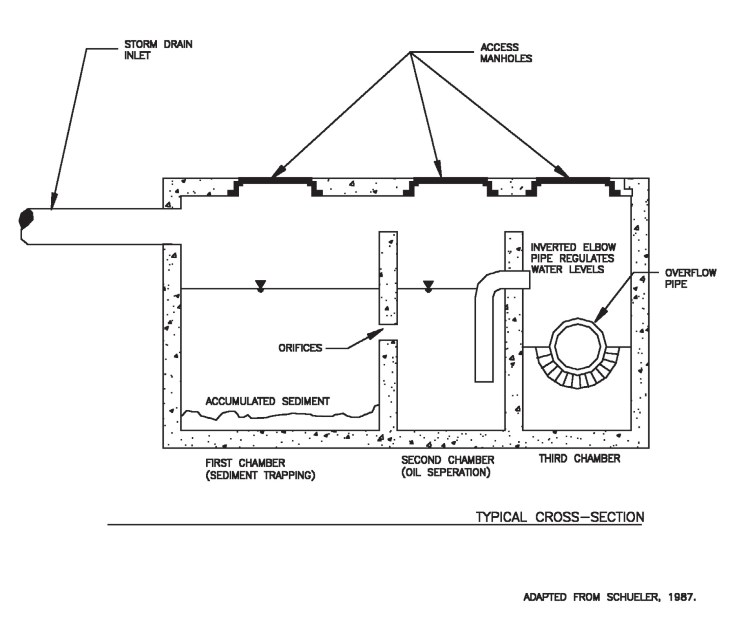

Spill control sc separators are the least expensive and complex of the three. Description oil water separators are multi chambered devices designed to remove hydrocarbons from stormwater runoff as it moves through the device. Different design criteria must be used in sizing and selecting a separator for a hydrocarbon stream based on the composition of the fluid mixture. 33 2 1 design oil separators shall be divided into three compartments by baffles or berms.