Oily Water Separator Marpol Regulations

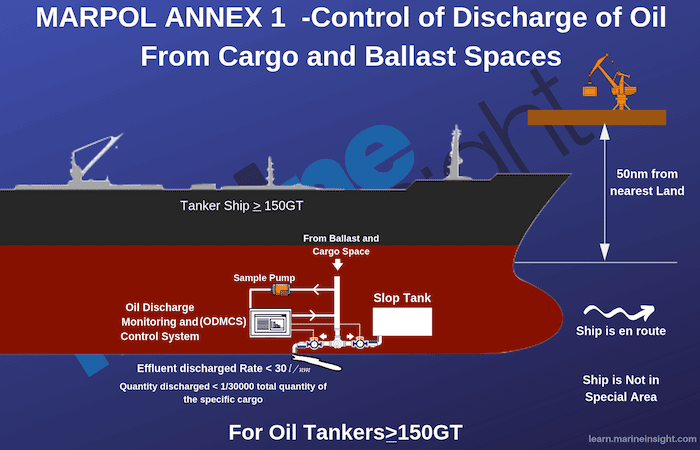

The ship is in route.

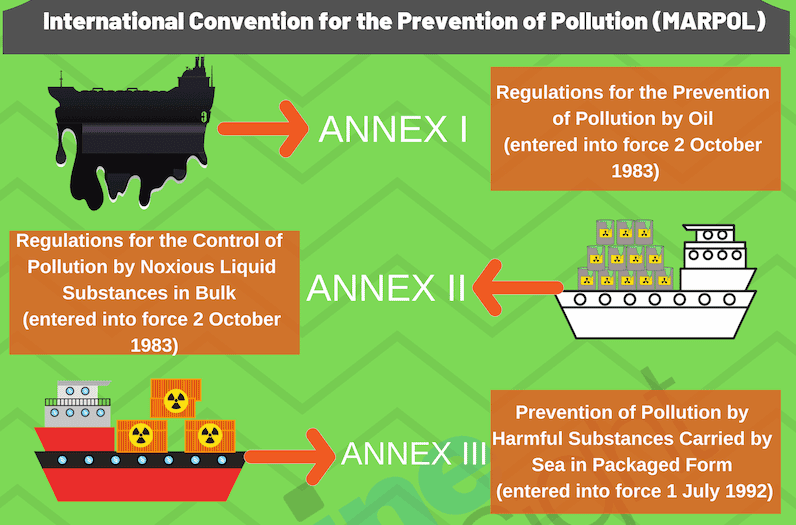

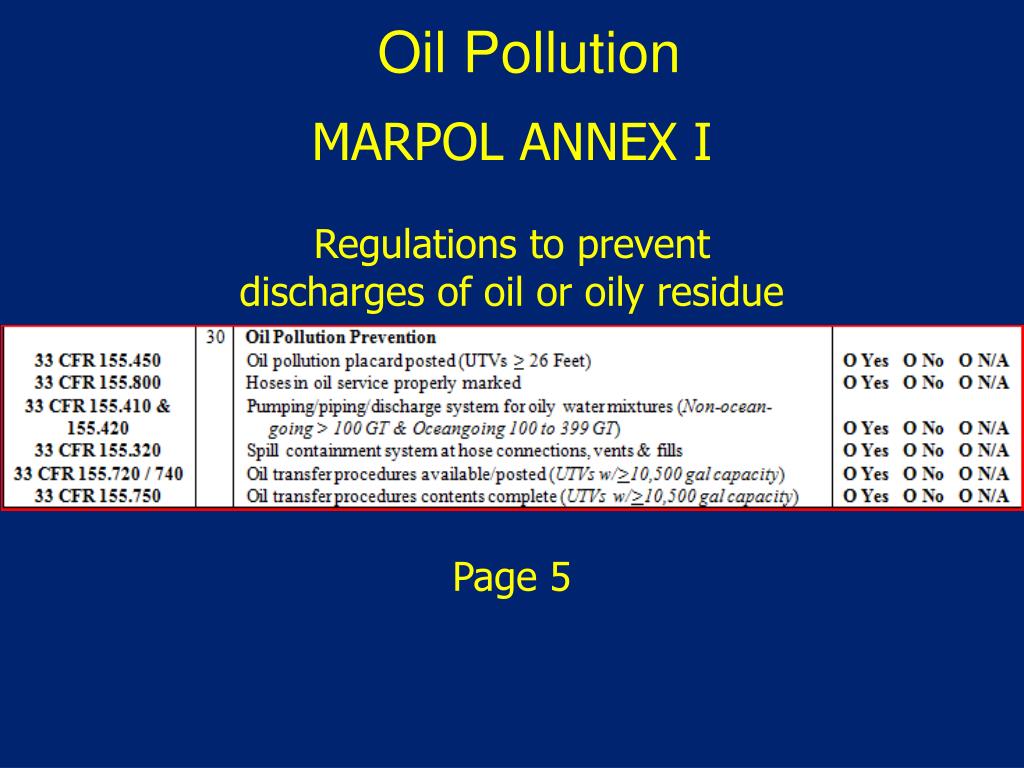

Oily water separator marpol regulations. This was superseded by the requirement for oil tankers delivered from 1996 onwards to be fitted with a double hull. Uninspected ships and foreign ships oily water separating equipment and bilge alarms must be approved under either 46 cfr 162 050 or marpol 73 78 annex i. An oily water separator is a piece of equipment specific to the shipping or marine industry. The marpol convention in 1983 introduced a number of radical new concepts such as a requirement for new oil tankers to be fitted with segregated ballast tanks so as to obviate the need to carry ballast water in cargo tanks.

The oily mixture does not originate from cargo pump room bilges on oil tankers. For ships above 400 grt such discharge from engine room is permitted provided. Note to 155 380 b. Within regulation 15 of marpol annex i there are no distance from land requirements for operation of the ows.

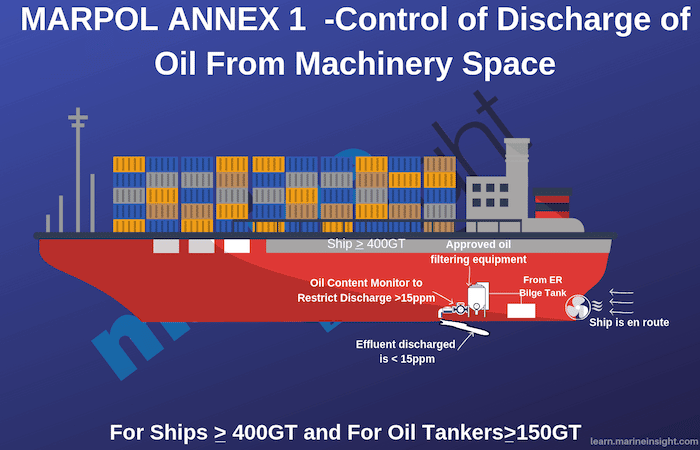

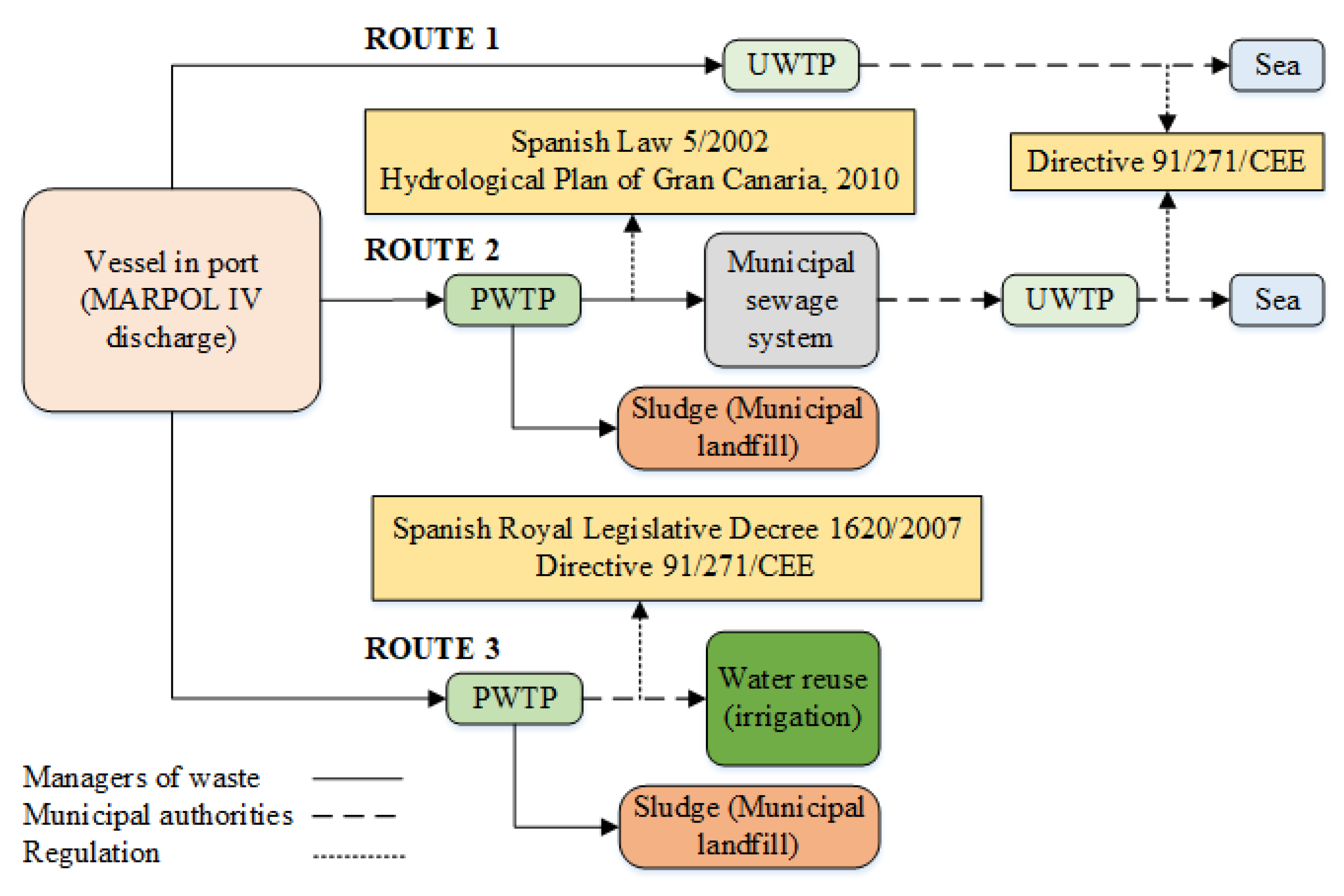

Important oily water separator ows requirement. The ocm provided with the oily water separator must be tamper proof the ocm must activate and sound an alarm whenever freshwater. The marpol convention contains detailed regulations designed to avoid pollution by oil or any other substance. The convention is divided into six annexes dealing with the prevention of pollution by oil noxious liquid substances in bulk harmful substances carried by sea in packaged form sewage garbage and air pollution.

Only oily mixture is allowed to be discharged provided they are filtered by oily water separator and follow the 15 ppm limit. These discharges of waste water must comply with the requirements laid out in marpol. Under marpol regulations any non processed oil or oily mixture is not allowed to be discharged overboard. The oil content of the effluent without dilution does not exceed 15 parts per million 4.

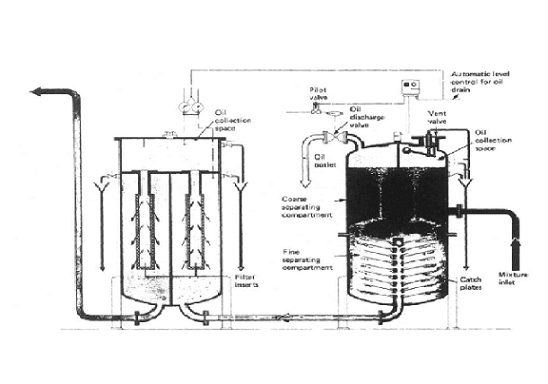

It is used to separate oil and water mixtures into their separate components. More than one hundred bilge separators have been certified by the u s. 6 1 2 the capacity of the supply pump should not exceed 110 of the rated capacity of the 15 ppm bilge separator with size of pump and motor to be stated on the certificate of type approval. If your vessel is within a special area other considerations apply.

This page refers exclusively to oily water separators aboard marine vessels. Inspected ships oily water separating equipment and bilge alarms must be approved under 46 cfr 162 050. The oily mixture is processed through an oil filtering equipment meeting the requirements of regulation 14 of this annex 3. Coast guard to meet 46 cfr 162 which implements marpol annex i regulations in the u s.

As per the mepc 107 49 the bilge alarm or an oil content monitors which provides for internal recording of alarm. The re circulating facility should be so configured as to prevent under all operating conditions any by pass of the oily water separator. They are found on board ships where they are used to separate oil from oily waste water such as bilge water before the waste water is discharged into the environment.