Oil Water Separator Design Pdf

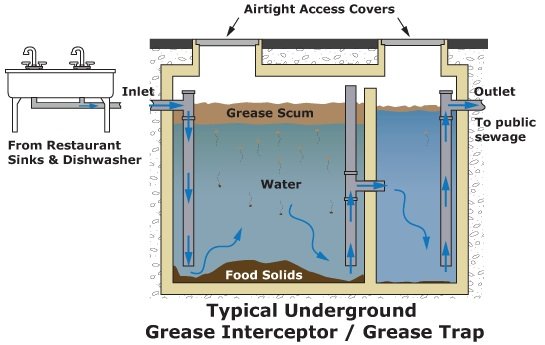

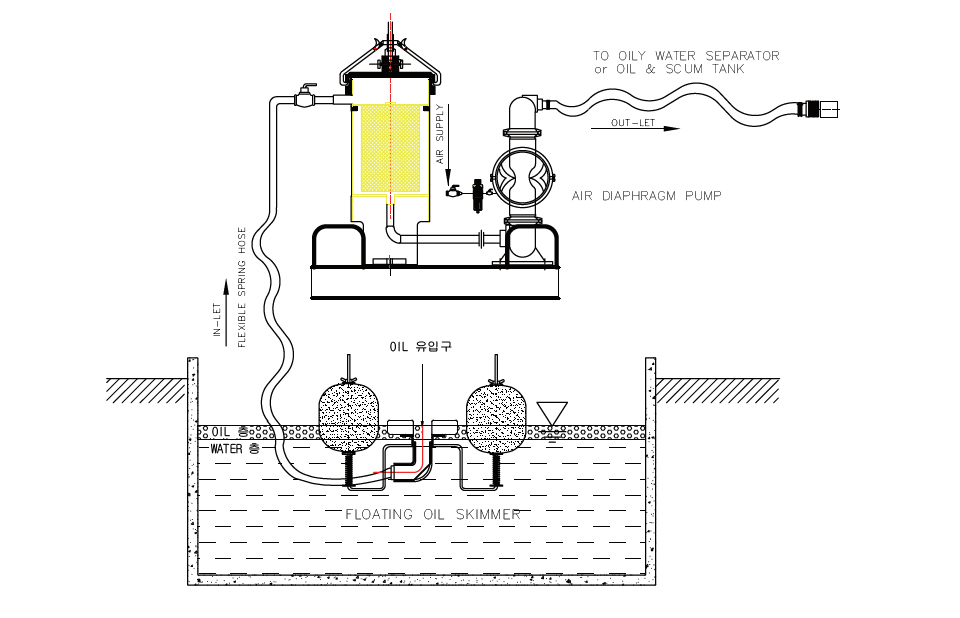

Proper oil water separator design will allow for the removal and storage of accumulated oil and sludge from the separator to ensure that the accumulated products do not effect the operation of the separator.

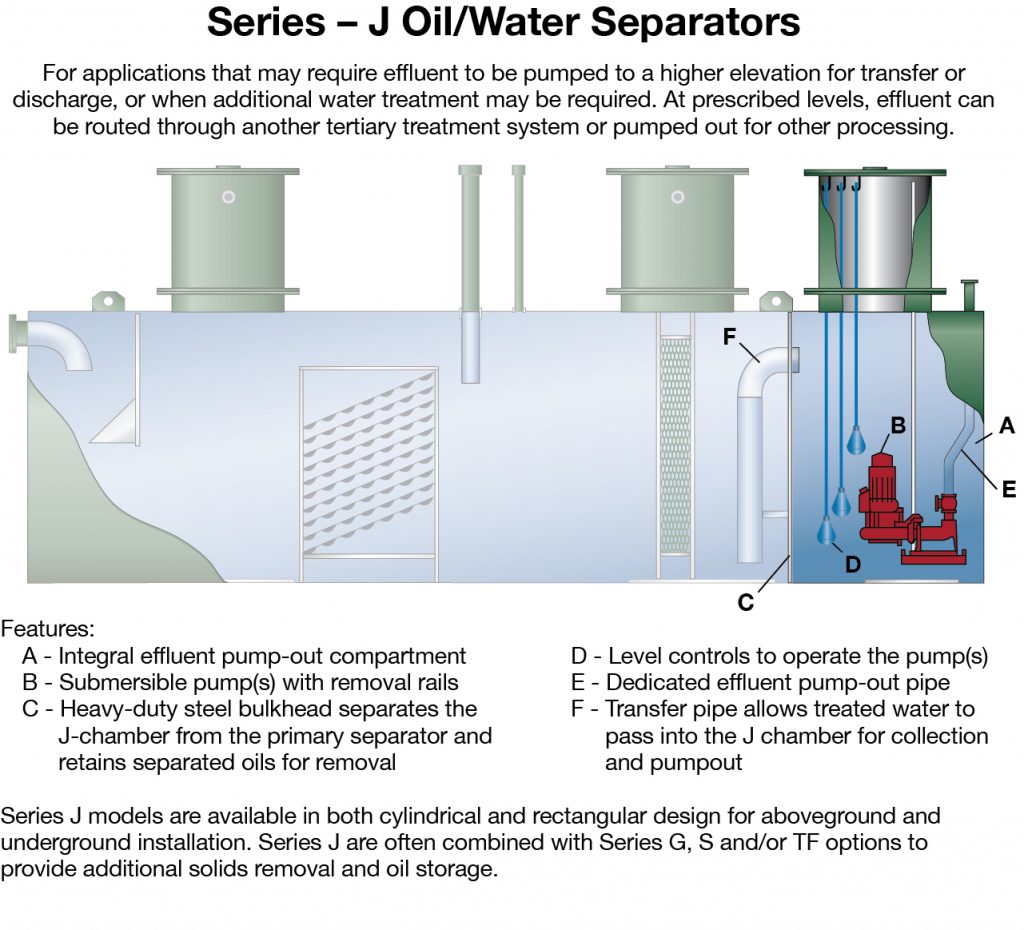

Oil water separator design pdf. Additional storage may be required. This chapter explains the applicability of the spcc rule to ows and clarifies the exemption for certain uses including equipment vessels and containers that are not specifically. Chapter 5 oil water separators 5 1 introduction the intended use of an oil water separator s ows determines whether the separator is subject to the spcc regulations and if so what provisions are applicable. This coalescing media improves the use of conventional steel basin oil water separators by providing improved effluent or by allowing higher flow rates of wastewater.

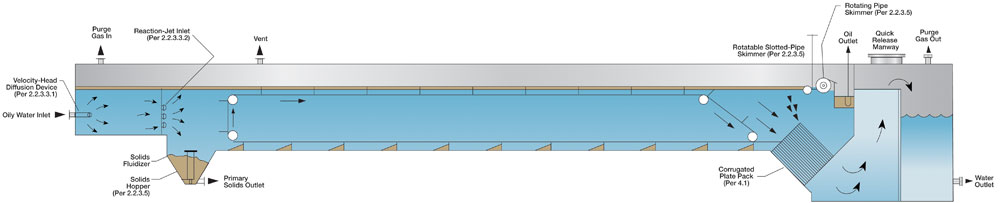

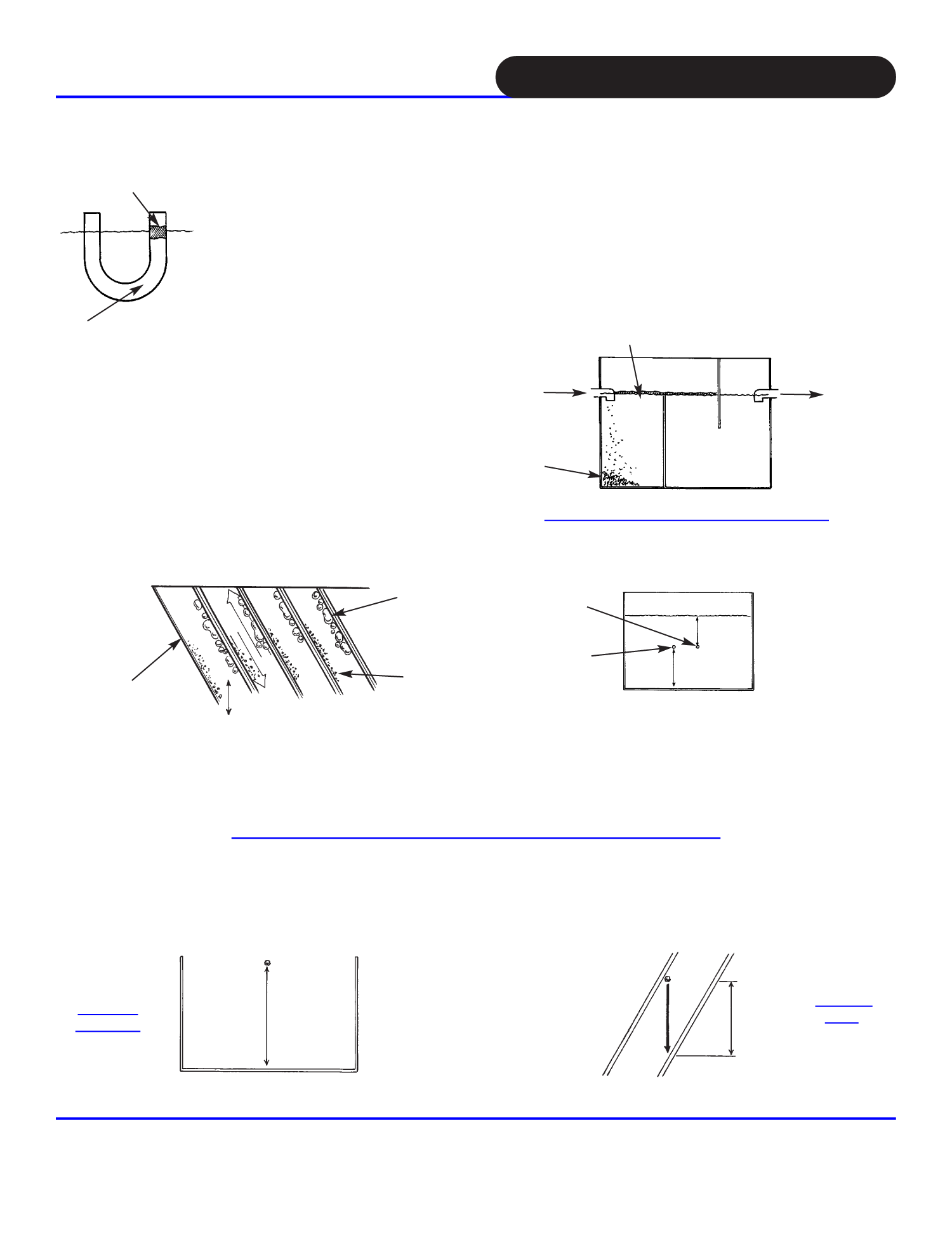

Industrial facilities have a number. Oil water separators plastic parallel plate packs are designed to enhance the separation of oil from water through added horizontal surface area and by creating less turbulent flow. In the case of. The ongoing benefits of low operating and low maintenance costs and the sale of recyclable oil usually.

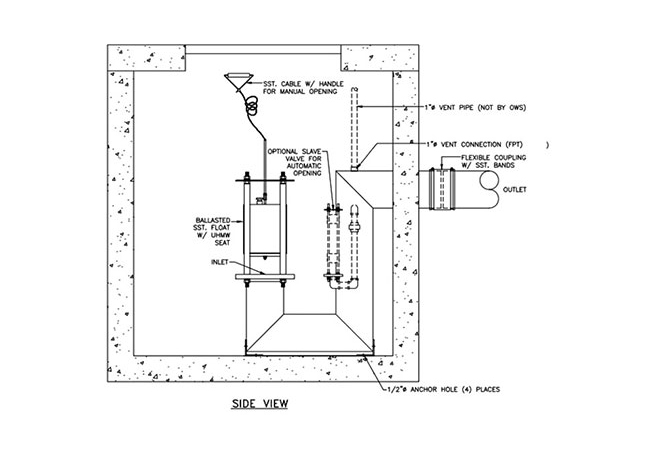

Design of conventional and parallel plate oil water separator systems requires proper characterization of the wastewater establishment of the design flow and required effluent quality sizing of. No absorbents are. Emulsifying agents detergents and soaps designed to remove oily grime from equipment vehicles or other components can adversely affect the operation of a gravity oil water separator. Mohr separations research inc.

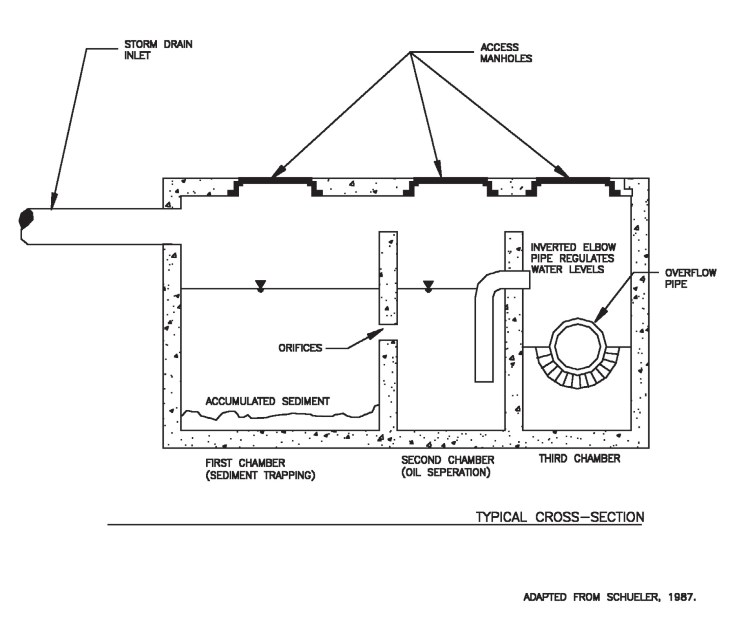

Drainage system and mix with the water in the separator then the oil in the spill will rise to the surface. Api separators are gravity type separators and are usually equipped with oil removal facilities. If the separator is to be used for spill containment it should be ensured that the separator can hold the anticipated spill volume. 33 1 2 types of separator api tanks see figure 33 1 and plate separators are the more efficient oil separators.

In the case of low pressure oil wells the liquid phase will be large in volume as compared to the gas phase. Lewisville tx 75077. Different design criteria must be used in sizing and selecting a separator for a hydrocarbon stream based on the composition of the fluid mixture. Environmental regulation of oil in water discharges is increasingly becoming more stringent.

Outweigh the slight added expense of the initial designs. 1278 fm 407 suite 109. The liquids from the gas phase is accomplished by passing the well stream through an oil gas or oil gas water separator. Because oil water separators operate using gravity as the operating principle their design is more difficult and requires more expertise than the design of filtration or other systems that operate under pressure.